Expert Tips for Ensuring Security During Comprehensive Lift Repair Work Treatments

In the world of detailed lift repair treatments, security stands as an extremely important worry that requires thorough attention to information and adherence to developed procedures. As the complicated interplay of equipment and human treatment unravels, a strategic method to safety and security comes to be the cornerstone for successful fixing operations.

Safety And Security Gear Needs

The safety and security gear needs for lift repair treatments are important to make certain the well-being of upkeep workers. Proper safety gear not only secures workers from prospective hazards but likewise enhances efficiency and precision during repair service jobs. When working on lifts, maintenance workers should comply with stringent safety and security protocols by using ideal gear such as construction hats, safety and security goggles, handwear covers, steel-toed boots, and high-visibility vests. These things are designed to give security versus head injuries, eye damages, hand injuries, foot injuries, and improve presence in the work setting to stop accidents.

Construction hats are essential for protecting against head injuries from bumping or falling objects right into overhead structures. Safety goggles secure the eyes from particles, chemicals, or sparks that might be produced during fixing job. Gloves give hand defense from cuts, burns, or electrical shocks, while steel-toed boots use foot security from heavy things or equipment. High-visibility vests ensure that upkeep workers are easily seen by others, decreasing the risk of accidents because of inadequate visibility. By strictly adhering to safety and security equipment demands, upkeep workers can reduce threats and work effectively to preserve and fix lifts.

Tools Inspection List

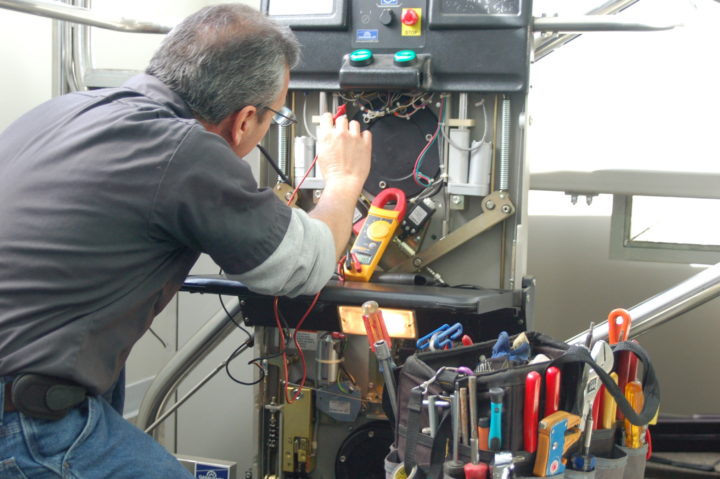

To guarantee the maintenance personnel's safety and the proper functioning of lifts, a comprehensive devices assessment list is essential prior to beginning any type of repair service procedures. lift breakdown. This list needs to consist of a thorough exam of all parts such as cords, pulley-blocks, electric systems, and safety devices. It is vital to evaluate for any indicators of damage, deterioration, or damages that might compromise the lift's structural integrity or operational efficiency

In addition to mechanical components, the examination checklist need to encompass safety features like emergency brakes, limitation switches, and overload sensors. These safety and security systems play a crucial function in preventing mishaps and guaranteeing customer protection throughout lift operation.

In addition, verifying the calibration of control systems, confirming proper ventilation and lighting within the lift shaft, and checking for any type of obstructions or particles are vital action in the assessment procedure. Normal maintenance and adherence to the tools examination list not only enhance safety and security procedures however additionally prolong the life-span of the lift system, minimizing the possibility of expensive repair services or unanticipated failures.

Danger Recognition Methods

Making use of methodical evaluation techniques, risk identification strategies are employed to determine prospective threats within lift repair service procedures. One usual method is the Work Security Analysis (JSA), where each step of the repair process is very carefully evaluated to recognize potential risks and figure out the best safety Read Full Article and security procedures to alleviate them.

Emergency Situation Response Preparedness

With an emphasis on guaranteeing swift and reliable action to unpredicted scenarios, emergency situation action readiness is an essential facet of maintaining security throughout lift repair work treatments. Prioritizing emergency preparedness involves establishing clear interaction networks, assigning certain roles and obligations, and performing regular drills to test action times and procedures.

Trick elements of emergency feedback preparedness consist of having readily easily accessible initial aid sets, fire extinguishers, and emergency call details plainly presented. It is imperative to train all workers associated with lift repair treatments on emergency action protocols, consisting of exactly how to securely evacuate the area in instance of a fire or other emergencies.

In addition, creating a detailed emergency situation reaction strategy particular to lift repair work situations can help minimize possible risks and make certain a timely and collaborated feedback in the event of an event. Routinely upgrading this strategy and reviewing based upon lessons gained from past drills or occurrences is necessary to continuously enhance precaution during lift repair work procedures.

Ongoing Safety Training

Consistent education and training in safety and security methods is a basic component of guaranteeing the continuous safety of workers throughout lift repair service procedures. Ongoing safety training plays a critical duty in maintaining workers educated concerning the most up to date safety and security standards, methods, and best practices webpage in the industry (lift repair). By offering regular training sessions, workers can stay current on possible dangers, safe work treatments, and emergency procedures details to raise repair service environments

Normal safety and security training additionally helps enhance the importance of adhering to security standards and procedures in any way times. It infuses a safety-conscious frame of mind amongst workers, advertising a culture of security within the work environment. Additionally, recurring training enables employees to refresh their expertise and abilities, enhancing their preparedness to manage any type of unexpected safety and security difficulties that may occur throughout lift repair work operations.

To make sure the performance of continuous security training, it is essential to tailor the content to the details dangers and needs related to lift repair procedures - lift breakdown. Employers should regularly analyze training needs, provide opportunities for hands-on technique, and encourage open communication concerning safety problems among all personnel entailed in lift fixing operations

Verdict

Finally, making sure safety and security during detailed lift repair work treatments is vital for avoiding mishaps and injuries. By adhering to safety equipment needs, performing tools evaluations, recognizing risks, planning for emergencies, and offering recurring safety training, workers can minimize risks and produce a safe workplace. Prioritizing safety and security measures and remaining cautious throughout the repair service procedure will certainly assist shield both workers and the tools being serviced.

When working on lifts, maintenance personnel must stick to stringent safety and security procedures by using ideal equipment such as difficult hats, security goggles, gloves, steel-toed boots, and high-visibility vests. One usual method is the Task Security Evaluation (JSA), where each action of the repair work process is very carefully analyzed to identify possible dangers and establish the best safety and security measures to mitigate them.Continuous education and learning and training in safety protocols is a fundamental element of making certain the continuous security of workers during lift repair work treatments.Routine safety and security training additionally assists reinforce the significance of adhering to security guidelines and procedures at all times. By complying with safety gear needs, carrying out equipment evaluations, recognizing dangers, preparing for emergency situations, and providing ongoing security training, employees can reduce risks and produce a risk-free work atmosphere.

Comments on “Comprehending Platform Lift Dimensions: Vital for Efficient Lift Service”